Accurate Cone Penetration Testing Across New Zealand

Topdrill Geotech offers state-of-the-art CPT services to deliver precise and reliable data for any geotechnical project.

Accurate Soil Data with CPT

CPT efficiently measures geotechnical properties by pushing a cone penetrometer into the ground at a constant rate, with sensors tracking resistance, friction, and pore water pressure. For geothermal areas, temperature sensor cones offer additional data, providing detailed insights into soil stratigraphy, density, strength, and other critical parameters.

Applications

- Foundation Design

- Accurate soil profiles help in designing safe and efficient foundations for buildings, bridges, and other structures.

- Site Investigation

- CPT is essential for assessing soil conditions before construction, ensuring project feasibility and safety.

- Environmental Studies

- CPT aids in the evaluation of soil contamination and the assessment of remediation needs.

Benefits

- Precision & Accuracy

- Our state-of-the-art CPT equipment and rigorous testing procedures guarantee precise and accurate soil property measurements.

- Rapid Data Collection

- CPT is a fast and efficient testing method, allowing for quick data acquisition and analysis, which helps expedite project deadlines.

- Comprehensive Soil Profiles

- CPT provides continuous and detailed profiles of soil properties, enabling better-informed design and construction decisions.

- Versatile In-Situ Testing

- In-Situ offers accurate subsurface data by minimizing soil disturbance, making it ideal for various soil types and environments, from soft clays to dense sands, in both urban and remote locations.

- Cost-Effective

- By providing rapid, high-quality data, CPT reduces the need for extensive and costly lab testing.

Other Types of CPT

With a variety of CPT tests, we use the technique best suited for the job, ensuring

precise and reliable results every time.

Seismic Cone Penetration Testing (sCPT)

sCPT is an advanced geotechnical investigation technique that combines traditional Cone Penetration Testing (CPT) with seismic measurements. By measuring shear wave velocity alongside standard CPT parameters, sCPT provides critical insights into soil stiffness, density, and liquefaction potential. **

sCPT offers a powerful tool for geotechnical engineers to design safer, more resilient structures and infrastructure.

Applications

- Foundation Design

- Accurate soil profiles help in designing safe and efficient foundations for buildings, bridges, and other structures.

- Seismic Hazard Assessment

- sCPT is essential for evaluating soil stiffness, liquefaction potential, and overall seismic site response.

- Site Investigation

- CPT is essential for assessing soil conditions before construction, ensuring project feasibility and safety.

- Environmental Studies

- CPT aids in the evaluation of soil contamination and the assessment of remediation needs.

Benefits

- Comprehensive Soil Profiles

- CPT provides continuous and detailed profiles of soil properties, enabling better-informed design and construction decisions.

- Assessment of Dynamic Soil Properties

- By measuring shear wave velocity, sCPT provides crucial information on soil stiffness, density, and potential for liquefaction.

Standard Penetration Testing

Standard Penetration Testing (SPT) is an in-situ dynamic penetration test offering valuable insights into the geotechnical engineering properties of soil. An SPT hammer drives a 51mm Raymond sampler at the bottom of a drive rod to recover soil samples, counting the number of blows over the last 300mm of penetration to give an ‘N value’ (indicating soil strength).

Dynamic Probe Super Heaving Testing

Dynamic Probe Super Heaving Testing (DPSH) is a continuous dynamic test which records the number of blows per 100mm to give an ‘N value,’ which is another effective testing method we offer.

Thin Wall Push Tube Sampling

Perfect for collecting undisturbed samples, this technique is essential for accurate contaminant analysis and soil characterization.

Trust Topdrill Geotech with all

your CPT needs

Experience & Expertise

Our team of skilled professionals has years of experience in geotechnical testing and analysis.

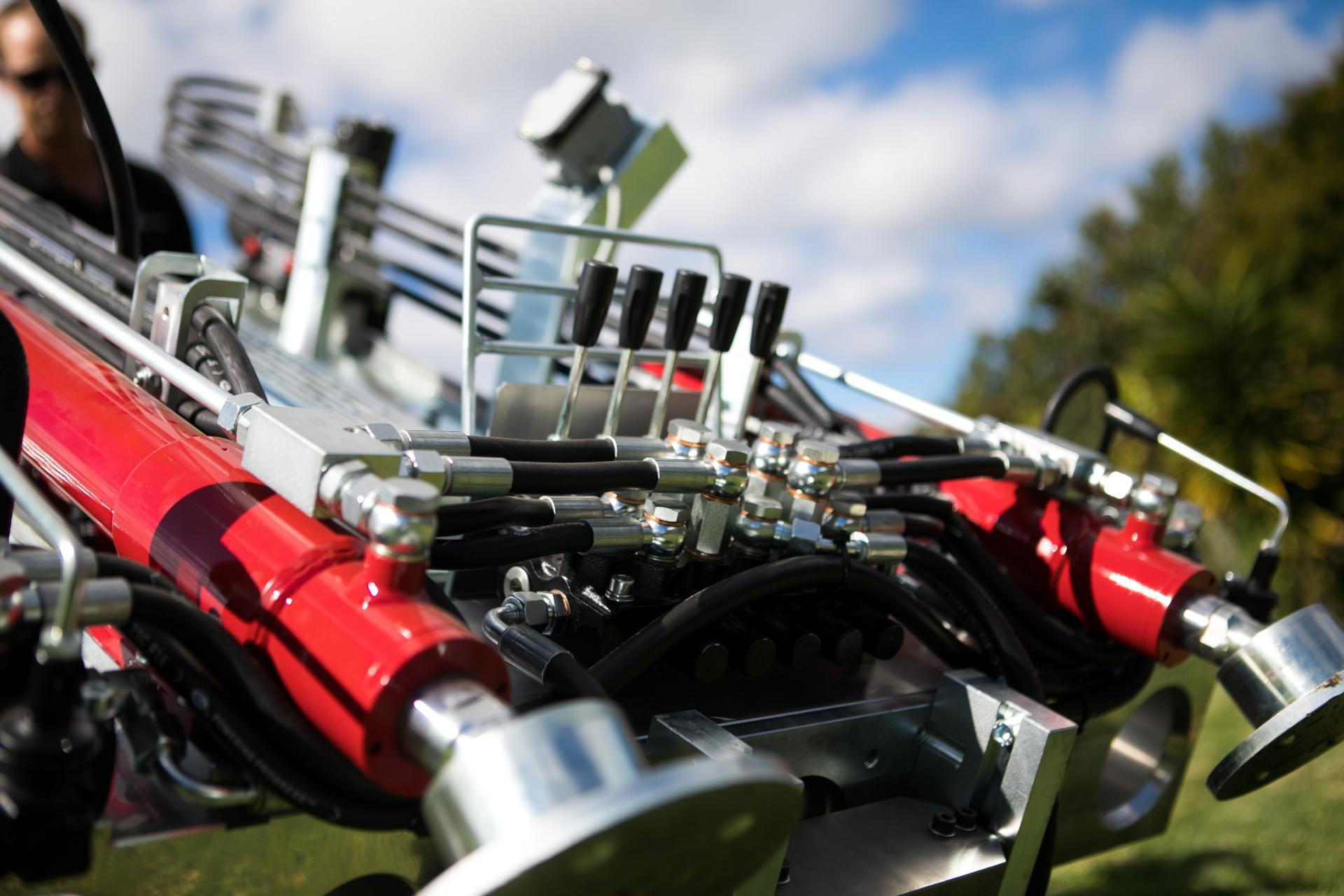

Advanced Equipment

We utilise the latest CPT technology to ensure the highest level of accuracy and reliability.

Client-Focused Approach

We work closely with our clients to understand their specific needs and deliver customised solutions.

Health & Safety

The safety and wellbeing of our personnel and the environment is managed by significant investments in training, equipment, and procedures.